Inside the World of Sakai Knife Artisans: Craftsmanship Born from 600 Years of Tradition

If you’ve ever held a handcrafted Sakai knife, you’ve felt the weight of centuries of Japanese knife craftsmanship resting in your hands. These blades aren’t just tools — they are cultural artifacts born from a 600-year lineage of artisans, each preserving techniques passed from master to apprentice.

Today, we step inside this world, uncovering the stories behind Sakai knife artisans, how their legendary reputation was forged, and why their work continues to define excellence for chefs and enthusiasts worldwide.

Why Sakai Became the Heart of Japanese Knife Craftsmanship

During the 16th century — spanning the turbulent Sengoku era to the early Edo period — tobacco culture arrived in Japan through Portuguese traders. Along with tobacco came small cutting blades used to slice the leaves for smoking, an early precursor to modern cigarette preparation.

But these imported knives had a problem: they simply weren’t sharp enough.

As tobacco cultivation spread rapidly across Japan, demand grew for sharper, more reliable blades. Sakai’s skilled metalworkers rose to the challenge, creating what were soon known as “Tobacco Knives,” applying the same forging precision that would later define Sakai’s kitchen knives.

The quality difference was unmistakable. Sakai-made knives were significantly sharper and more durable than their overseas counterparts, leading the Tokugawa Shogunate to officially recognize their superiority. Blades stamped with the certification “Sakai Kiwame” were granted exclusive production rights — a status symbol that quickly spread throughout Japan and solidified Sakai’s reputation for exceptional craftsmanship.

By the 1800s, these knife-making techniques evolved into what is now one of Japan’s most revered crafts: Sakai kitchen knives — known worldwide for extraordinary sharpness, geometry, and attention to detail.

The history is not just long — it is uninterrupted. Many of today’s master craftsmen are direct descendants of Edo-period blacksmiths.

The Multi-Craftsman System — A Tradition Unlike Anywhere Else in Japan

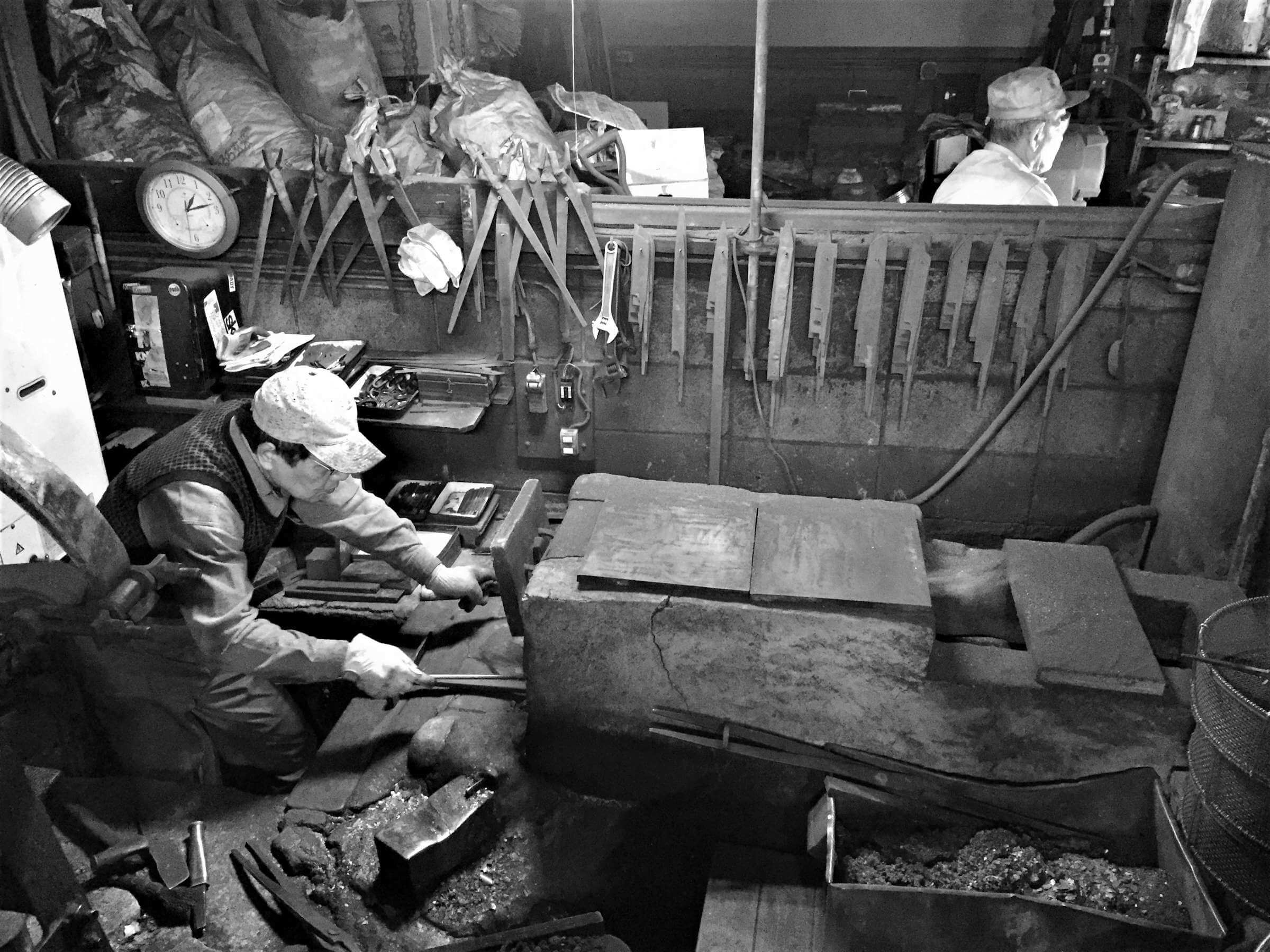

One of the most extraordinary parts of sakai knife history is the unwavering specialization of artisans. Unlike other regions, where a single smith may complete the entire knife, Sakai’s system intentionally divides the craft into three separate mastery paths.

1. The Blacksmith

The blacksmith forges the core steel, shapes the profile, and establishes the soul of the blade. Using hammer, anvil, and charcoal-fired heat, they ensure the steel’s grain structure and hardness align with the intended performance.

2. The Sharpener (Hatsuke process)

After forging, the blade is passed to the sharpener — a role considered as prestigious and difficult as forging itself. Togishi spend decades perfecting their craft to create exceptional edge geometry and flawless cutting performance.

3. The Handle Maker (Edo-style craftsmen)

Handle makers craft wa-handles from ho wood, walnut, ebony, and other hardwoods. They ensure comfort, balance, and elegance — elements that set Sakai knives apart.

Artisans Who Carry the Flame Today

What makes Sakai so remarkable is how this ancient structure continues unchanged. Modern artisans still train for decades, and many represent the fourth, fifth, or even sixth generation of craftsmen.

At Hasu-Seizo, our connection to this world is especially personal. Through our family’s lineage with Sakai Takayuki (Aoki Hamono), we have deep roots in one of Sakai’s most respected workshops. Their work with elite blacksmiths preserves the uncompromised standards of the region.

How a Sakai Knife Is Made — Step-by-Step Craftsmanship

1. Steel Selection

Artisans choose between Shirogami, Aogami, Ginsan, VG10, and other steels based on intended performance.

2. Forging & Heat Treatment

The blacksmith repeatedly heats and hammers the steel, forming its spine, edge, and grain structure. Heat treatment is where the knife’s performance is truly born.

3. Rough Shaping

The smith defines profile and thickness, preparing the blade for sharpening.

4. Honing

The sharpener refines the bevels, cutting edge, and geometry, creating either a mirror polish or traditional kasumi finish.

5. Handle Crafting & Fitting

The handle maker shapes and burns in the handle, balancing the blade perfectly.

6. Final Inspection

Every knife undergoes human inspection — not machine testing — before receiving the Sakai stamp.

What Makes Sakai Knives So Revered by Chefs Worldwide

- Unmatched sharpness from master sharpeners

- Exceptional edge retention

- Timeless designs refined over centuries

- Premium steels chosen for performance

- Balance and ergonomics that feel natural

How to Choose a Sakai Knife for Your Kitchen

For beginners: Stainless Steel Santoku or Gyuto. For intermediates: Aogami Super Gyuto or Nakiri. For collectors: Honyaki blades or limited artisan works.

Where Tradition Meets the Modern Kitchen

Today, Sakai knives sit at an intersection of tradition and modern demand. As mass-produced knives flood the market, collectors and chefs increasingly look for blades that are handmade, personal, and tied to genuine craftsmanship.

Experience Genuine Sakai Craftsmanship with Hasu-Seizo

As a family-owned shop with roots in Sakai, Hasu-Seizo is uniquely positioned to share this world with customers across the U.S. Every knife we curate comes directly from certified Sakai workshops.

Hold a Sakai knife in your hand — and feel the history yourself.