If you’ve ever held a finely crafted Japanese kitchen knife, you know there is something extraordinary about it. The balance, the sharpness, the way it slices cleanly through ingredients—it all comes down to the steel. Understanding the different Japanese knife steel types is essential because each alloy dramatically affects cutting feel, edge longevity, and overall performance. For centuries, Japanese blacksmiths have perfected the art of steelmaking, drawing from the same traditions that once produced samurai swords. Today, those skills live on in kitchen knives, where the type of steel determines not only performance but also the knife’s personality.

Whether you’re a home cook buying your first Japanese knife, a professional chef seeking a reliable workhorse, or a gift buyer searching for something meaningful, understanding knife steels is the key to finding the right blade. This guide explores each major steel type—from traditional White and Blue carbon steels to modern stainless options like VG-10, ZA-18, and AUS-10, and advanced powdered alloys such as SG2 and SRS13. You can choose the right steel for your cooking style, maintenance preferences, and long-term needs.

Quick overview: Japanese knife steel types range from traditional carbon steels like Shirogami and Aogami to modern stainless and powdered steels such as VG-10, ZA-18, SG2, and SRS13. The best steel for Japanese knives depends on your cooking style, how often you sharpen, and how much maintenance you’re willing to do.

Why Steel Matters in Japanese Knives

- Sharpness potential: How finely it can be sharpened and how “bitey” the edge feels on food.

- Edge retention: How long it stays sharp between sharpening sessions.

- Toughness: How well it resists chips, cracks, and abuse.

- Corrosion resistance: How well it withstands rust and staining from moisture and acidic ingredients.

- Ease of sharpening: How quickly and easily you can restore the edge on whetstones.

The best Japanese knives are a marriage of steel quality and blacksmithing skill. A superbly heat-treated carbon steel blade can outperform a mediocre powdered steel knife. That’s why understanding the steel—and how it has been treated—helps you select a knife that will perform beautifully in your specific kitchen, whether you’re breaking down whole fish, slicing sashimi, or meal-prepping vegetables for the week.

Because different Japanese steel types vary widely in hardness, corrosion resistance, and sharpening feel, choosing the right alloy is just as important as choosing the shape of the knife.

Understanding the Basics of Knife Steels

Before getting into the detailed differences between Japanese knife steel types, it helps to understand the broader categories of carbon vs stainless steel and how alloy composition shapes knife performance.

Carbon vs Stainless Steel

Carbon Steel (such as White or Blue steel) is revered for its outstanding sharpness and ease of sharpening. However, it contains little or no chromium, so it is highly reactive: it will quickly form a patina and can rust if left wet or dirty. Carbon steel rewards attentive cooks who don’t mind wiping their blade often.

Stainless Steel (like VG-10, Ginsan, ZA-18, or AUS-10) contains enough chromium to resist rust, generally at or above ~13%. These steels are more forgiving in busy kitchens, tolerate brief contact with moisture, and require less day-to-day fuss—though they still shouldn’t go in a dishwasher.

Rockwell Hardness (HRC)

The Rockwell scale (HRC) measures hardness and is one of the most important specs for comparing Japanese knife steels. Most Japanese knives fall between 60–66 HRC:

- 58–60 HRC: Softer, tougher, easier to sharpen; better for heavy use and rough cutting (common for AUS-10).

- 60–62 HRC: Balanced hardness, good edge retention with reasonable toughness (typical for VG-10 and Ginsan).

- 62–65 HRC: Very hard, excellent edge retention but more brittle; best for precise cutting and careful technique (often seen in Aoniko (Blue #2), ZA-18, SG2).

Heat Treatment

Two knives forged from the same steel can behave very differently depending on the blacksmith’s heat treatment. Precise control of heating, quenching, and tempering determines how hard, tough, and stable the steel is in real use. This is where centuries of Sakai craftsmanship truly shine—the tempering and finishing techniques bring out the best in each alloy, whether it’s a traditional Shirogami yanagiba or a modern SG2 gyuto.

Traditional Japanese Knife Steels

White Steel (Shirogami)

Among all Japanese knife steel types, the traditional carbon steels stand out for their purity, sharpening feel, and precision. White Steel (Shirogami) is considered the purest form of Japanese carbon steel, made with very few impurities. Its extremely fine-grained structure allows it to take an ultra-refined, razor-sharp edge that is prized for precision work. Shirogami typically falls in the 60–65 HRC range, depending on the sub-type and the maker’s heat treatment.

Because it lacks alloying elements like chromium, White Steel has very low corrosion resistance. It will patina quickly and can rust if left wet or dirty, so it demands diligent care but rewards you with some of the most satisfying sharpening and cutting performance available.

- Shirogami #1: The highest carbon content of the three, White #1 can be hardened toward the top of the 63–65 HRC range. It offers the longest-lasting edge and the sharpest potential, making it ideal for extremely precise cuts like sashimi or fine vegetable work. However, it can be slightly more brittle and a bit slower to sharpen than #2, and it will react quickly to acidic foods if not wiped promptly.

- Shirogami #2: The most balanced of the White Steels, typically hardened around 61–63 HRC. White #2 sharpens very easily, holds an excellent edge, and is more forgiving than #1 in daily use. It is widely favored by sushi chefs and serious home cooks who want the purity and feedback of high-carbon steel with slightly less risk of chipping.

- Shirogami #3: With lower carbon content and hardness often around 60–62 HRC, White #3 is softer and more forgiving, making it easier to sharpen and maintain. While it doesn’t hold an edge as long as #1 or #2, it is a good entry point for those new to carbon steel, providing traditional feel and patina development with a bit more toughness.

Maintenance tips: Wipe dry immediately after cutting, especially when working with acidic ingredients like citrus, tomatoes, or onions. Avoid leaving the knife on a damp cutting board or in the sink. A thin coat of camellia oil when storing for longer periods will help prevent rust.

Blue Steel (Aogami Family)

Blue Steel (Aogami) begins with a Shirogami-style base and adds chromium and tungsten to increase wear resistance and edge retention. In practice, Aogami behaves like a more durable, higher-end version of White Steel: it still sharpens beautifully and takes a fine edge, but it holds that edge longer and can be slightly more tolerant of real-world use. While the added chromium improves corrosion resistance a bit, Blue Steel is still considered a reactive carbon steel and requires similar care to Shirogami.

- Aogami (Blue #1): Shares the same high carbon content as Shirogami #1, but with added chromium and tungsten. Typically hardened around 63–65 HRC, Blue #1 offers excellent edge retention and wear resistance while maintaining the ability to take on an exceptionally sharp edge. It’s well suited to professional chefs who value long-lasting performance and are comfortable with precise technique and attentive maintenance.

- Aoniko (Blue #2): Has the same carbon content as Shirogami #2, with the addition of chromium and tungsten for greater durability and improved edge retention. Commonly found in the 62–64 HRC range, Blue #2 strikes a beautiful balance between sharpness, retention, and sharpenability, which is why so many artisans and chefs love it as a “do-everything” carbon steel.

- Aogami Super: Maintains the same high carbon level as Blue #1 but adds extra chromium and tungsten, plus molybdenum and vanadium. These additional alloying elements boost hardness, strength, and wear resistance and provide a modest bump in corrosion resistance compared to other carbon steels. Aogami Super can be hardened to around 63–65 HRC and is often considered one of the most advanced traditional carbon steels available, delivering exceptional edge life for professionals who sharpen correctly and avoid abuse (like twisting or cutting hard bone).

Maintenance tips: Treat Blue Steel like a slightly more robust White Steel—wipe frequently, avoid prolonged contact with acids, and store completely dry. Expect a patina to form over time, which will help protect the blade while adding character.

Shirogami vs Aogami Comparison

| Attribute | Shirogami (White Steel) | Aogami (Blue Steel) | Notes / Similarities |

|---|---|---|---|

| Base Type | Very pure high-carbon steel with minimal alloying elements. | High-carbon steel based on Shirogami, with added alloying elements. | Both are traditional Japanese carbon steels. |

| Key Alloying Elements | Primarily iron and carbon; extremely low impurities. | Iron and carbon plus chromium and tungsten (and in Aogami Super, molybdenum and vanadium). | Aogami builds on Shirogami with added alloys for durability. |

| Typical Subtypes | Shirogami #1, #2, #3 | Aogami (Blue #1), Aoniko (Blue #2), Aogami Super | Both families offer stepped variations in hardness and toughness. |

| Hardness Range (HRC) | Approx. 60–65 HRC depending on subtype and maker. | Approx. 62–65 HRC, slightly higher average for edge retention. | Both are harder than most Western steels and can take very fine edges. |

| Edge Retention | Excellent, especially in Shirogami #1 and #2, but wears faster than Aogami. | Very high to extremely high; added alloys significantly improve wear resistance. | Aogami generally holds an edge longer than comparable Shirogami. |

| Sharpening Ease | Very easy to sharpen, superb feedback on whetstones. | Still sharpens well, but slightly more wear-resistant and can feel “harder” on stones. | Shirogami is preferred when frequent sharpening and ultra-fine edges are priorities. |

| Corrosion Resistance | Very low; highly reactive and quick to patina or rust if not dried. | Low to medium; slightly better than Shirogami due to chromium, but still reactive. | Both are carbon steels and require careful drying and storage. |

| Toughness | Moderate; softer variants (Shirogami #3) are more forgiving. | Moderate to good; improved wear resistance and strength from alloying elements. | Aogami can be a bit tougher in use, especially Blue #2 and Aogami Super. |

| Maintenance Level | High: frequent wiping, immediate drying, occasional oiling. | High: same habits as Shirogami, though slightly more forgiving. | Care routines (wipe, dry, oil) are essentially the same for both. |

| Cutting Feel | Extremely “clean” and smooth, with very crisp feedback on the board. | Similar fine cutting feel, with a slightly more robust, “workhorse” character. | Both are known for precise, satisfying cutting sensations. |

| Typical Applications | Yanagiba, usuba, precision slicers, knives for delicate prep and sashimi. | Workhorse gyuto, deba, sujihiki, knives where long edge life is critical. | Shirogami skews toward ultra-precision; Aogami toward performance workhorses. |

| Ideal User | Chefs and enthusiasts who value pure sharpness and love sharpening. | Professionals and serious home cooks who want longer edge life and durability. | Both reward good technique and attentive care; not ideal for very casual users. |

Modern Japanese Stainless Steels

These stainless alloys are among the most popular choices in any Japanese knife steel guide, offering home cooks and professionals a balance of durability and performance.

VG-10

VG-10 is arguably the most famous Japanese stainless steel for kitchen knives and one of the most common core steels in Japanese chef knives. Typically hardened to around 60–62 HRC, it offers an excellent balance of edge retention, corrosion resistance, and ease of maintenance. VG-10 includes chromium for rust resistance and elements like vanadium and molybdenum to refine the grain and increase wear resistance.

VG-10 takes a fine, aggressive edge and is commonly used as the core steel in Damascus-clad blades, combining performance with striking aesthetics. It’s a fantastic choice for home cooks and professionals who want a sharp, long-lasting edge without the intensive care requirements of carbon steel.

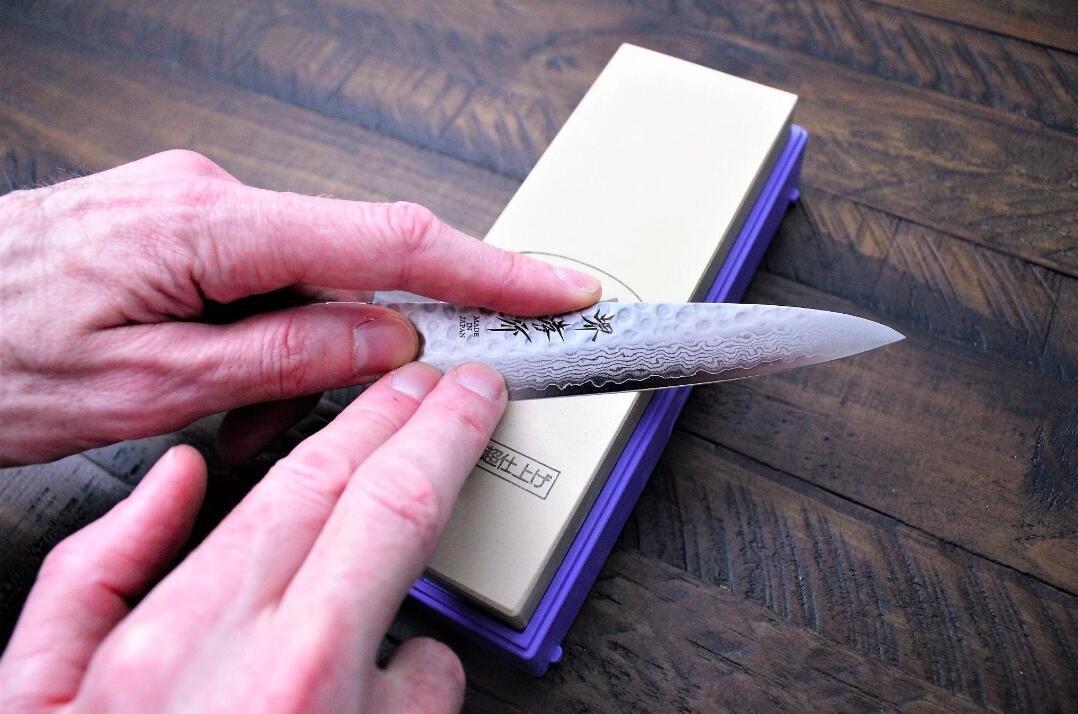

Maintenance tips: Rinse and dry after use, avoid harsh detergents, and never put VG-10 knives in the dishwasher. Sharpen with a 1000–3000 grit stone for regular maintenance and finish with 4000–6000 grit for a silky, polished edge.

Ginsan (Silver #3)

Ginsan, or Silver #3, is a high-quality stainless steel designed to mimic the cutting feel of carbon steel while offering much better corrosion resistance. It is usually hardened to around 60–62 HRC, allowing it to take a very fine edge with good retention.

Ginsan is admired for its smooth sharpening feedback and clean, refined edge. Many chefs choose Ginsan when they want the tradition and precision of a Shirogami-style edge but work in environments where true carbon steel would be too high-maintenance.

Maintenance tips: Wipe dry after use and avoid soaking, but Ginsan is far more forgiving of brief moisture exposure than carbon steels. It sharpens quickly on standard water stones, making it ideal for users who appreciate regular touch-ups.

ZA-18

ZA-18 was developed as an upgrade to VG-10, with increased chromium (often ~18%) and added cobalt for extra hardness and strength. It is commonly hardened in the 60–63 HRC range, giving it excellent edge retention and very high corrosion resistance.

Because of this enhanced alloying, ZA-18 can feel a bit more “glass-like” on the stones than softer stainless steels, but rewards skilled sharpeners with a long-lasting, fine edge. It’s a strong choice for demanding professional kitchens where knives see constant use and frequent exposure to moisture.

Maintenance tips: ZA-18 is quite rust-resistant but still benefits from immediate rinsing and drying after use. Use quality cutting boards and avoid twisting or prying to reduce the risk of micro-chips at higher hardness levels.

AUS-10

AUS-10 is an accessible Japanese stainless steel often hardened around 59–61 HRC. It offers a very good balance of toughness, ease of sharpening, and corrosion resistance, making it popular for daily-use knives and for cooks transitioning from Western blades.

While its edge retention is not as high as VG-10 or ZA-18, AUS-10 is more forgiving under less-than-perfect technique and can handle slightly rougher tasks without chipping as easily. It’s a practical choice for busy home kitchens, line cooks, and anyone who values reliability and easy maintenance.

Maintenance tips: Clean and dry after use and avoid harsh scrubbers. AUS-10 responds well to regular touch-ups on a 1000–2000 grit stone or ceramic rod.

Powdered Steels (High-Performance Alloys)

SG2 / R2

SG2 (also known as R2) is a powdered metallurgy steel that uses a fine powder process to create an ultra-uniform grain structure. Typically hardened around 62–63 HRC, it delivers outstanding edge retention and the ability to be ground extremely thin behind the edge, resulting in lasers that glide through food. SG2 and other powdered metallurgy alloys often appear at the top of any best steel for Japanese knives discussion due to their edge life and ultra-fine grain structure.

SG2’s high hardness and wear resistance mean it is less forgiving of poor technique or very hard cutting surfaces. It excels in the hands of professionals and enthusiasts who prefer to sharpen less frequently but are careful to use proper cutting boards and avoid bones and frozen items.

Maintenance tips: Treat SG2 knives with respect—no twisting, prying, or scraping on hard surfaces. Use high-quality end-grain or soft plastic boards. Sharpen with quality water stones, starting around 1000–2000 grit and finishing with 4000–6000 or higher.

SRS13

SRS13 is another powdered steel engineered to balance high hardness and edge retention with improved toughness. Often hardened to around 61–63 HRC, it offers outstanding edge life while being slightly less brittle than some other high-hardness steels.

For chefs and serious home cooks who want the performance of a powdered metallurgy steel but are concerned about chipping, SRS13 can be an excellent choice. It maintains a very keen edge and is suitable for a wide range of precision tasks in a professional setting.

Maintenance tips: Care is similar to SG2—use gentle cutting techniques and appropriate boards. When sharpening, take your time on stones and avoid aggressive grinding to preserve the fine microstructure of the steel.

Damascus Steel – Function or Fashion?

While Damascus patterns vary, the core steel still determines performance, which is why understanding the underlying Japanese knife steel types remains essential when evaluating any Damascus knife. Modern Damascus cladding often provides beauty more than function, but it can still add subtle advantages such as food release and a slightly grippier surface. In most Japanese kitchen knives, the core steel—whether Shirogami, Aogami, VG-10, or SG2—does the actual cutting, while the Damascus layers protect and support it.

When choosing a Damascus knife, focus first on the core steel and then enjoy the layered patterns as a reflection of the maker’s artistry and the unique character of your knife.

Detailed Japanese Knife Steel Types Comparison (Best Knife Steel Chart)

This detailed best knife steel chart compares the most important Japanese knife steel types side by side. Use it to quickly understand how different Japanese steel types stack up in hardness, edge retention, corrosion resistance, maintenance needs, and ideal users so you can choose the best steel for Japanese knives for your own cooking style.

| Steel Type | Approx. HRC | Edge Retention | Corrosion Resistance | Toughness | Sharpening Ease | Maintenance Level | Typical Knife Types | Ideal User |

|---|---|---|---|---|---|---|---|---|

| White #1 (Shirogami #1) | 63–65 | Very High | Low | Low–Medium | Moderate | High (fully reactive, needs oiling) | Yanagiba, usuba, high-precision gyuto | Sushi chefs, precision-focused cooks |

| White #2 (Shirogami #2) | 61–63 | High | Low | Medium | Easy | High (reactive, regular wiping) | Yanagiba, deba, gyuto, petty | Professional chefs, serious home cooks |

| White #3 (Shirogami #3) | 60–62 | Medium | Low | Medium–High | Very Easy | Medium–High (still reactive, but forgiving) | All-purpose gyuto, entry-level traditional knives | Beginners to carbon steel, enthusiasts wanting a softer feel |

| Blue #1 (Aogami #1) | 63–65 | Very High | Low–Medium | Medium | Moderate | High (reactive, patina-forming) | Gyuto, deba, sujihiki | Experienced cooks and pros who value long edge life |

| Blue #2 (Aoniko / Aogami #2) | 62–64 | High–Very High | Low–Medium | Medium–High | Moderate | High (reactive, similar to other Blue steels) | Workhorse gyuto, nakiri, deba | Professionals and enthusiasts seeking a balanced carbon steel |

| Aogami Super | 63–65 | Extremely High | Low–Medium | Medium | Harder | High (reactive but slightly improved with added alloys) | High-performance gyuto, sujihiki | Expert chefs and sharpeners wanting maximum performance |

| VG-10 | 60–62 | High | High | Medium | Moderate | Low–Medium (stainless but still needs drying) | All-round gyuto, petty, santoku, Damascus-clad knives | Home cooks and gift buyers seeking versatile stainless |

| Ginsan (Silver #3) | 60–62 | High | High | Medium | Easy | Low–Medium (stainless, easy to live with) | Professional gyuto, petty, single-bevel knives | Chefs who want carbon-like feel with stainless convenience |

| ZA-18 | 60–63 | Very High | Very High | Medium | Moderate | Low (strong stainless performance) | High-use gyuto and santoku in busy kitchens | Professionals needing durability and rust resistance |

| AUS-10 | 59–61 | Moderate | High | High | Easy | Low (very forgiving stainless) | Everyday gyuto, utility knives | Beginners, line cooks, home cooks wanting toughness |

| SG2 / R2 | 62–63 | Extremely High | High | Medium–Low | Moderate | Medium (stainless but sensitive to abuse) | Laser gyuto, sujihiki, fine slicers | Professional chefs and enthusiasts wanting long edge life |

| SRS13 | 61–63 | Very High | High | Medium | Moderate | Medium (stainless, slightly tougher than some powdered steels) | High-performance gyuto, daily pro use | Cooks wanting premium performance with added toughness |

Choosing the Right Steel for Your Cooking Style

There is no single “best” steel—only the best steel for Japanese kitchen knives for your specific habits, experience level, and preferences. Choosing the right steel means matching hardness, corrosion resistance, and maintenance needs to how you actually cook.

- Busy home cooks who want low maintenance: Look to stainless steels like VG-10, Ginsan, ZA-18, or AUS-10. They resist rust, perform well, and only require basic care.

- Precision-focused cooks and sushi lovers: Consider Shirogami #1 or #2 and Blue Steels (especially Aoniko (Blue #2)) for maximum sharpness and control.

- Professionals who want long-edge life: High-performance steels like Aogami Super, SG2, and SRS13 shine in demanding environments where frequent sharpening is difficult.

- Those new to Japanese knives: Start with something forgiving and versatile, such as AUS-10, VG-10, or Ginsan, before moving into more reactive or higher-hardness steels.

Caring for Different Knife Steels

To maintain performance and extend the life of your Japanese knife, match your care routine to the steel type:

- Carbon Steels (White & Blue): Wipe the blade clean and dry after each use—especially with acidic foods—and never leave it in the sink or on a wet board. Allow a natural patina to form and, for longer storage, apply a thin coat of camellia oil.

- Stainless Steels (VG-10, ZA-18, Ginsan, AUS-10): Rinse and dry promptly; avoid dishwashers and harsh scrubbers. Even though they are “stainless,” they are not “stain-proof,” so basic care still matters.

- Powdered Steels (SG2, SRS13): Use end-grain wood or soft plastic cutting boards and avoid chopping through bone, pits, or frozen food. Sharpen with quality water stones and use gentle strokes to preserve the fine microstructure.

For all steels, store knives on a magnetic strip, in a saya, or in a dedicated knife block—never loose in a drawer. Regular light sharpening and occasional stropping will keep your blade performing at its best for years.

Find Your Perfect Japanese Knife at Hasu-Seizo

From the purity of White Steel to the enhanced strength of Blue Steel, and from premium stainless alloys to advanced powdered metallurgy, the spectrum of Japanese knife steel types reflects centuries of refinement. Each alloy reflects generations of refinement, offering chefs and home cooks alike the opportunity to connect with centuries of craftsmanship every time they pick up a knife.

Ready to find your perfect match? Explore Hasu-Seizo’s curated collection of Japanese knives and choose the steel that truly fits your cooking style, routine, and culinary ambitions.