HASU-SEIZO'S JAPANESE KNIFE BUYING GUIDE - STEEL TYPES

Welcome to Hasu-Seizo's Japanese Knife Buying Guide—your ultimate resource for understanding the different steel types used in Japanese knives. Whether you’re an aspiring chef, a professional in the kitchen, a dedicated home cook, or looking for the perfect gift, this guide will help you choose the best knife based on your needs.

How to Choose the Right Knife for You:

For Home Cooks: Stainless steel or clad steel knives offer excellent durability and ease of care, perfect for everyday use.

For Professionals: Carbon steel or powdered steel knives are ideal for the highest level of sharpness and control.

For Gift Buyers: Damascus or stainless steel knives are beautiful, functional, and versatile, making them thoughtful gifts.

At Hasu-Seizo, we are committed to craftsmanship and quality, offering a wide range of Japanese knives that cater to different needs and preferences. Explore our collection today and experience the unmatched precision of Japanese steel.

Let’s dive into the key steel types that define the precision, durability, and sharpness of our knives.

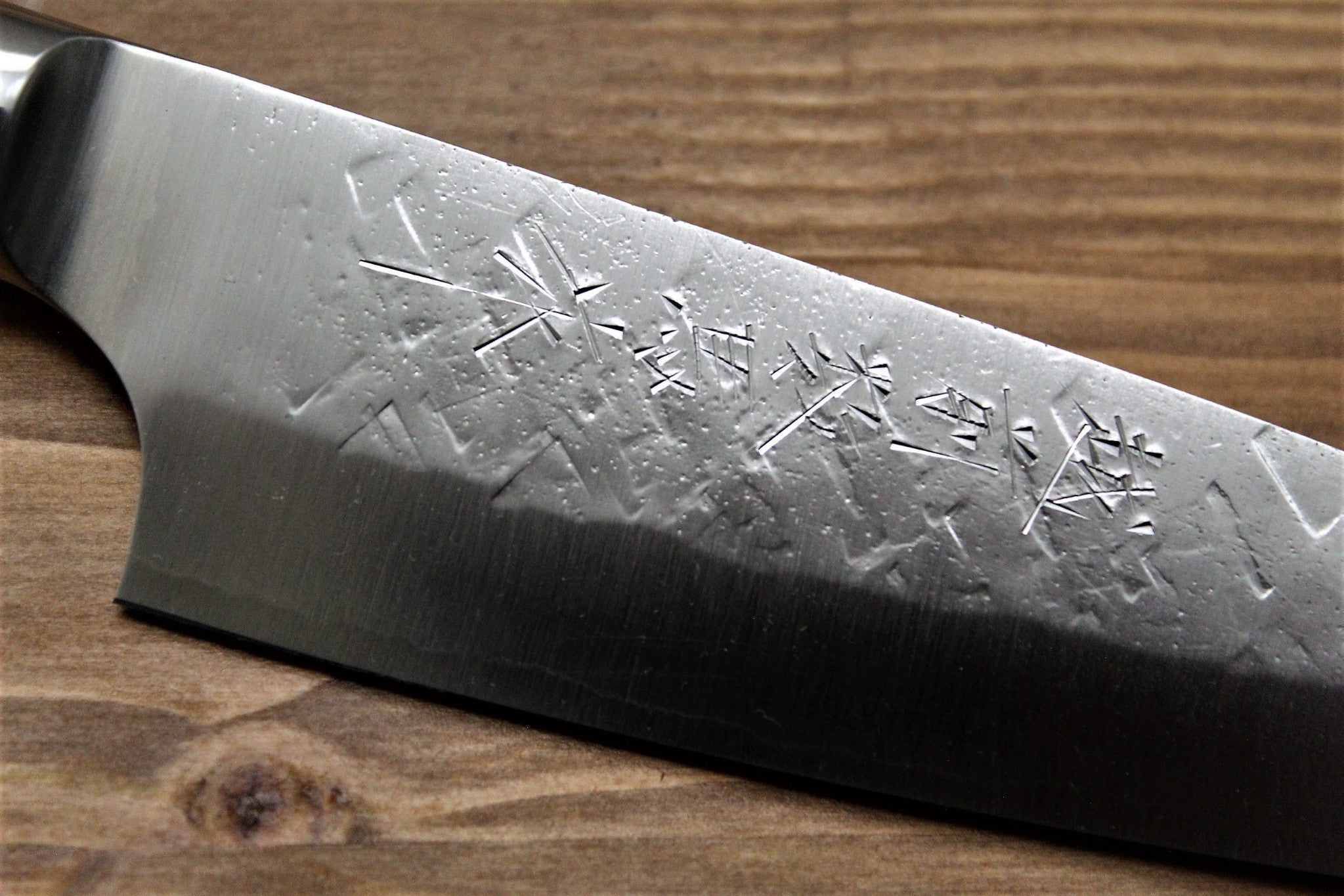

1) Carbon Steel Knives (HIGH-CARBON STEELS)

Carbon steel is renowned for its incredible sharpness and edge retention. These knives are favored by professional chefs and knife enthusiasts because they can be honed to a razor-sharp edge that stays sharp for a long time.

Best for:

Professionals, Chefs, Enthusiasts

Things to Consider:

Carbon steel knives require more care. They are prone to rust and patina, so regular cleaning and drying are essential.

Carbon Steel Best Sellers

Some of the most common Carbon Steel Knives Types include:

White Steel (Shirogami):

Known for its fine grain structure, White Steel is easy to sharpen and provides a smooth, precise cut. It’s excellent for those who want a traditional, ultra-sharp Japanese knife.

SHIROGAMI #1, SHIROICHIKO OR WHITE STEEL #1

Shirogami #1 (White Steel #1) has a higher carbon content than Shirogami #2, giving it superior edge retention but making it more brittle. It is a rare and prized material used in traditional Honyaki knives, crafted by only a few skilled artisans. For practical purposes, many chefs prefer Shirogami #2, as it's less brittle and easier to sharpen, making it ideal for everyday use.

SHOP SHIROGAMI #1 / WHITE STEEL #1 KNIVES

SHIROGAMI #2, SHIRONIKO OR WHITE STEEL #2

Shirogami #2 (White Steel #2) is a popular high-carbon steel used in traditional Japanese knives, known for being slightly less brittle and easier to sharpen than Shirogami #1 due to its lower carbon content. Chefs often prefer it for its balance of sharpness and durability, making it ideal for precise cuts of fish, vegetables, and garnish. Both steels allow for exceptionally fine cutting performance.

SHOP SHIROGAMI #2, SHIRONIKO OR WHITE STEEL #2Blue Steel (Aogami):

With added chromium and tungsten, Blue Steel is harder and more resistant to wear and corrosion than White Steel, making it ideal for high-performance cutting tasks and extended durability.

AOGAMI #1, AOICHIKO OR BLUE STEEL #1

Aogami, or Blue Steel #1, is similar to White Steel #1. The difference is the addition of tungsten and chromium to the material for added durability and corrosion resistance. These additions add specific qualities to already high-quality steel.

Shop Aogami #1 / Blue Steel #1 Knives

AOGAMI #2, AONIKO OR BLUE STEEL #2

Aoniko, or Blue Steel #2, is a popular high-carbon steel in Western-style Japanese knives. With 1.0-1.2% carbon, it resembles Shirogami #2 but includes tungsten and chromium for added durability and abrasion resistance, making it a reliable choice for kitchen knives.

Shop Aogami #2 / Blue Steel #2 Knives

AOGAMI SUPER OR BLUE SUPER STEEL

Aogami Super, or Blue Super Steel, includes all Blue Steel #1 elements, plus molybdenum and vanadium for added corrosion resistance and strength. With a 61-65 HRC hardness, its enhanced carbon and chromium levels make it the premier Yasugi steel, offering superior hardness and abrasion resistance.

Shop Aogami Super / Blue Super Steel Knives2) Stainless Steel Knives

Stainless steel knives offer the perfect balance between sharpness and low maintenance. They resist rust and staining, making them ideal for home cooks or professionals who prefer less maintenance without sacrificing performance.

Best for:

Home Cooks, Professionals, Gift Buyers

Things to Consider:

While stainless steel is more resistant to corrosion, it may not be as sharp or easy to sharpen as high-carbon steels. However, modern stainless steel alloys have greatly improved in terms of sharpness and durability.

Stainless Steel Best Sellers

Some of the most common Stainless Steel Knives Types include:

VG-10 Steel

This premium stainless steel is known for its excellent edge retention and corrosion resistance. It’s often used in high-quality Japanese knives, combining sharpness with ease of maintenance. Typically these knives have a HRC between 60 and 61. Damascus-knives often use VG-10 as the core, with Damascus Steel wrapped around them.

Shop VG-10 Knives

AUS-10 Steel

Another popular stainless steel option, AUS-10 is durable, corrosion-resistant, and offers decent sharpness. It’s a great choice for home cooks or those new to Japanese knives. This Japanese stainless steel offers slightly less chromium than VG-10.

Shop AUS-10 Knives

Ginsan / Silver No.3

This Japanese steel is very fine-grained stainless steel and can have an edge sharpness and edge retention similar to some high-carbon steels. This steel is generally thought to be slightly easier to sharpen than VG-10 while also slightly more susceptible to rust due to the lower chromium content.

Often, when Japanese chefs choose stainless steel over high-carbon steel types for their knives, they will choose Ginsan.

Shop Ginsan / Silver No.3 Knives

ZA-18

ZA-18, designed by Aichi to rival or surpass VG-10, is an impressive stainless steel known for outstanding edge retention and customer satisfaction. With higher carbon, chromium, molybdenum, and cobalt, ZA-18 offers greater strength and durability than VG-10, achieving 61-63 HRC for razor-sharp, long-lasting edges.

Shop ZA-18 Knives3) Powdered Steel Knives (High-Performance Steels)

Powdered steel knives represent the pinnacle of modern knife-making. These knives are engineered for extreme hardness, sharpness, and durability, combining the benefits of carbon and stainless steel. Some of the leading powdered steel types include:

Best for:

Professionals, Knife Enthusiasts, Precision Cutting Tasks

Things to Consider:

Due to their high hardness, powdered steel knives can be more difficult to sharpen. However, they deliver unmatched performance and are perfect for experienced users or those willing to invest in long-lasting sharpness.

SG2 (R2) Steel

SG2 is a high-end powder steel famed for its exceptional hardness, reaching up to 64 HRC, and superb edge retention. Resistant to wear and corrosion, SG2 is a top choice for professionals seeking lasting, razor-sharp performance. Its durability and reliability make it a standout in the Japanese kitchen knife world.

Shop SG2 Knives

SRS13 Steel

SRS13, developed by Nachi-Fujikoshi, is a high-performance powder metallurgy stainless steel that reaches HRC64 with heat treatment, offering sharpness and cutting speed. With flexible heat treatment options, SRS13 can balance hardness and resilience, reducing chipping compared to SG2/R2. This durability makes it a top choice for professionals and enthusiasts tackling demanding tasks.

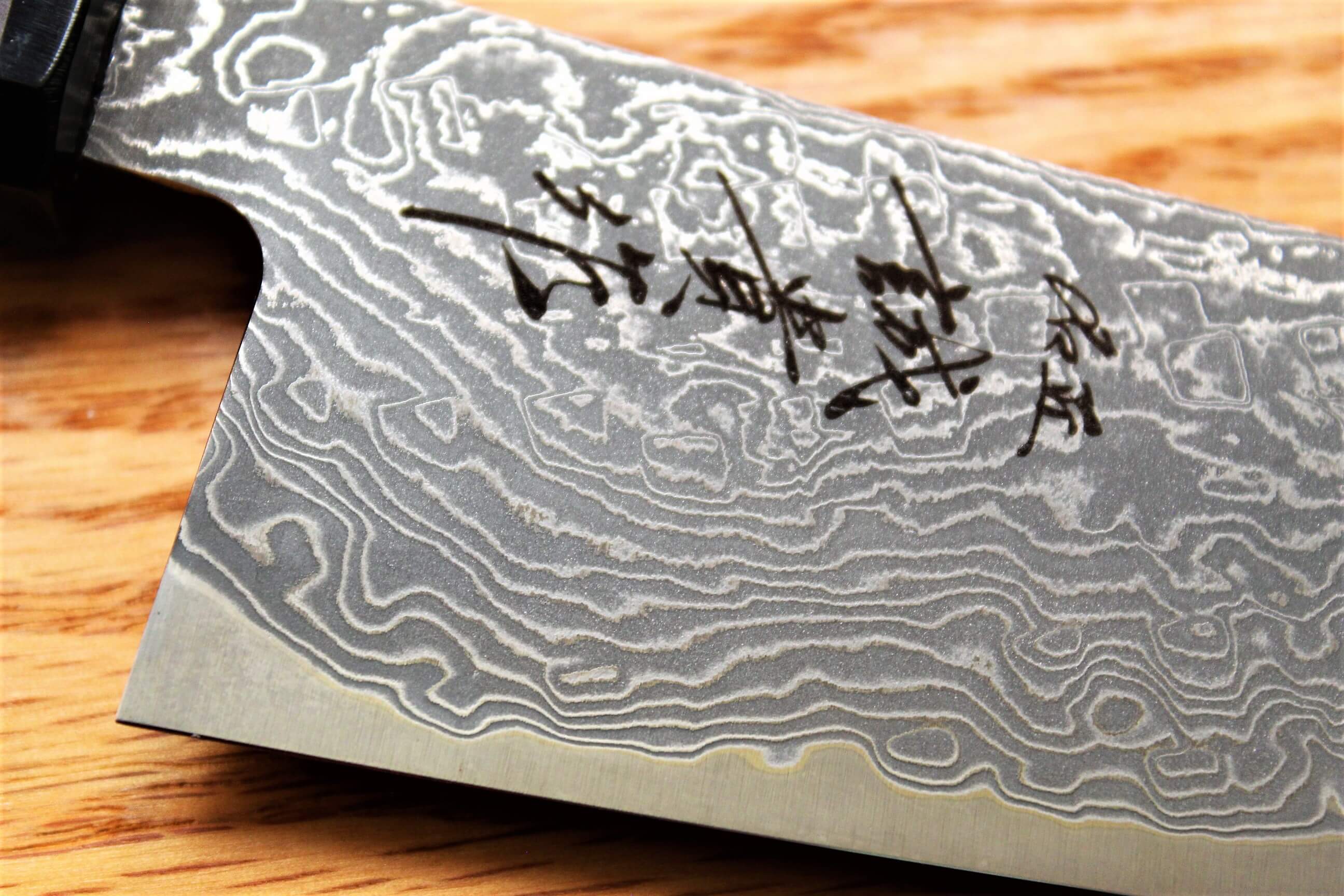

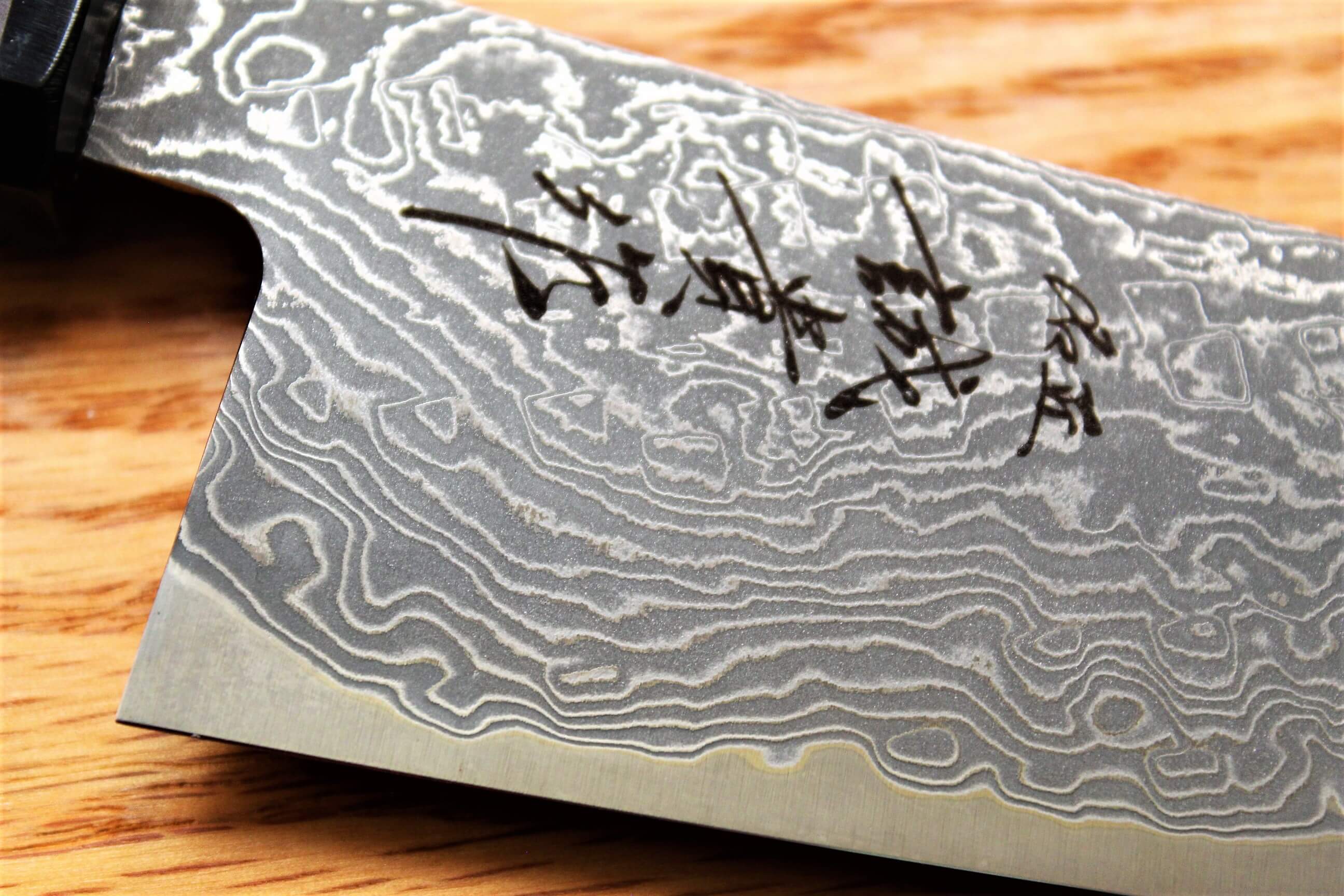

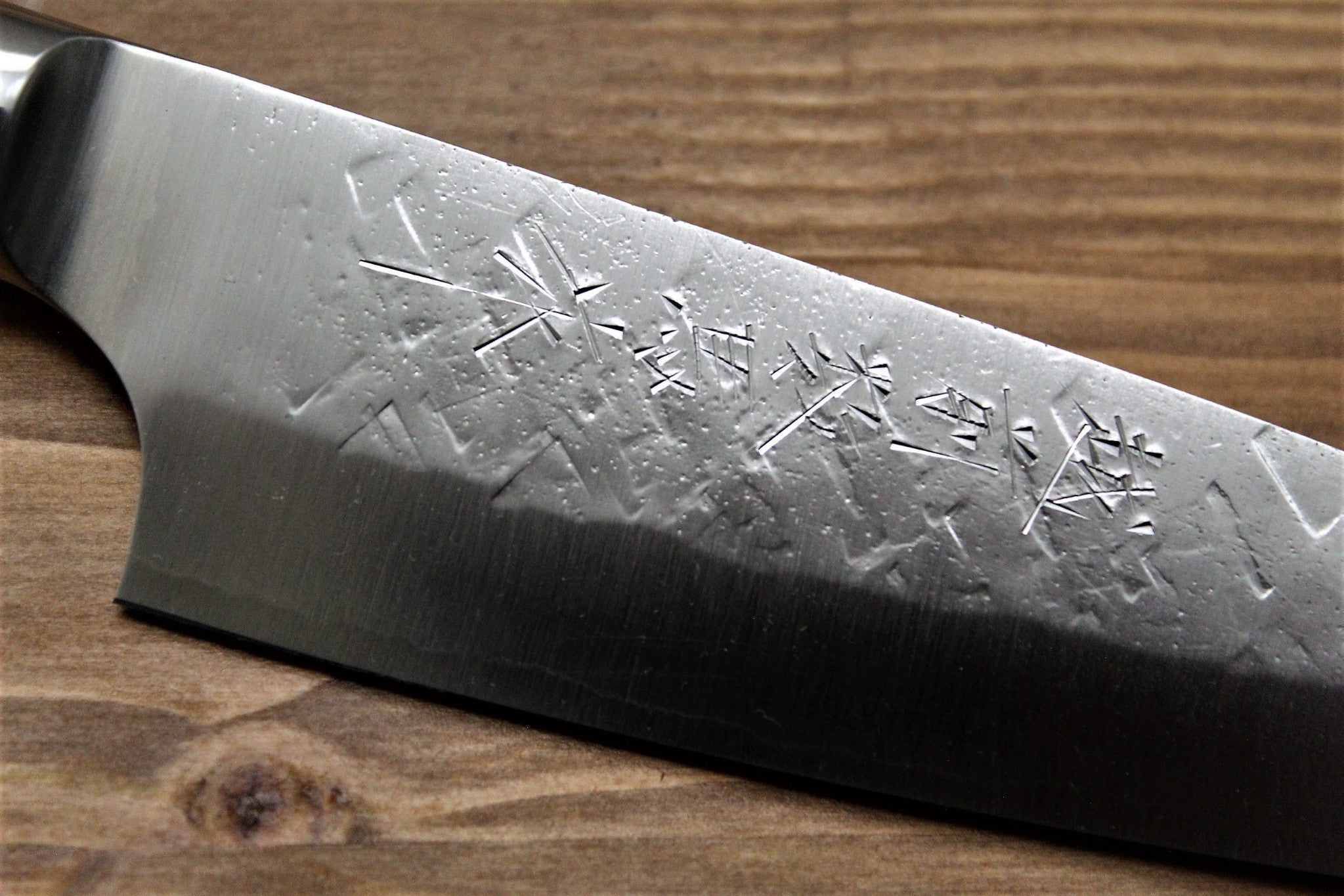

Shop SRS13 Knives4) Damascus Steel Knives

Damascus steel knives are renowned for their beautiful, patterned blades and high-quality performance. These knives are often made with a core of high-carbon or stainless steel, surrounded by layers of softer steel, which are then folded to create the stunning wave-like pattern.

Best for:

Gift Buyers, Enthusiasts, Home Cooks

Things to Consider:

Damascus steel is often chosen for its beauty as much as for its performance. While it’s functional, it also makes a wonderful gift or statement piece in any kitchen.

Stainless Steel Damascus

Combines the durability and low-maintenance of stainless steel with the stunning aesthetics of Damascus patterns.

Shop Stainless Steel Damascus Knives

High Carbon Steel Damascus

Offers the sharpness of carbon steel with the visual appeal of Damascus layering, though it requires extra care to prevent rusting.

Shop High Carbon Steel Damascus Knives5) Other Stainless Steel Options

MOLYBDENUM ("MOLY")

Molybdenum stainless steels are Japanese steels with higher molybdenum content than typical stainless steels. While all stainless steels contain 10.5% or more chromium, not all include molybdenum. This addition boosts corrosion resistance, making these steels ideal for kitchen knives.

SHOP MOLYBDENUM KNIVES

Inox

Inox is a general type of stainless steel, typically with a lower HRC than stainless steel types used in Japanese knives. The Inox used by Sakai Takayuki is typically AUS-8; often, this version of AUS-8 has molybdenum added to it for additional corrosion resistance. The HRC for this material is in the 58-59 range generally.

Shop Inox Knives

Swedish Steel

World-class Bohler-Uddeholm steel is the highest quality stainless steel material, and it has excellent sharpness, strength, and resistance to abrasion. Knives made of this type of steel are lightweight and easy to use.

Shop Swedish Steel KnivesBUY SUPERIOR-QUALITY JAPANESE CHEF KNIVES FROM HASU-SEIZO

Experience the timeless craftsmanship of Japanese sword-making in every Hasu-Seizo knife. Our expertly curated collection of Japanese steel kitchen knives empowers you to prepare authentic cuisine with unmatched precision and ease.

Each Hasu-Seizo knife is meticulously crafted by master artisans, tested to meet the highest standards of performance and quality. Whether for your kitchen or as a meaningful, auspicious gift, these knives embody tradition and excellence.

Browse our range today and elevate your culinary experience with the finest Japanese steel. Contact our team to discover more about our premium collection.