Filters

The Benefits of Molybdenum Steel Knives

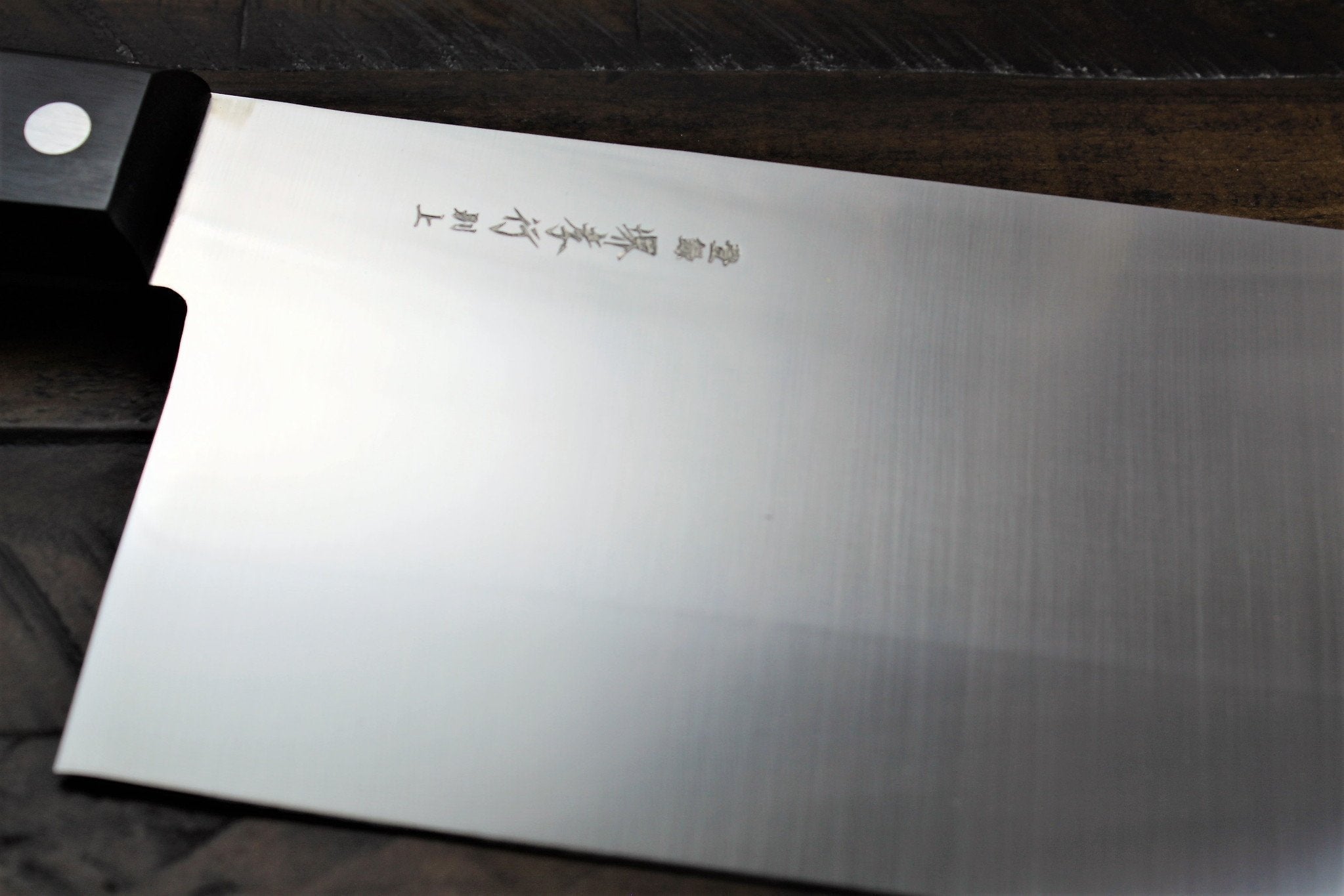

Like blacksmiths, blade sharpeners, and patterning artisans all contribute to fashioning swords, Japanese kitchen knives utilize different alloys in steel to cultivate the best blades.

Stainless steel always has at least 10.5% chromium, which helps resist corrosion. However, not all stainless steel uses molybdenum as an alloying element.

Molybdenum steel knives offer several benefits that make them popular among cooking enthusiasts. They resist corrosion even better than stainless steel alone, and the alloy’s added strength aids fine edge retention and durability. Molybdenum culinary knives are easier to sharpen than other alloys, enabling you to focus on food instead of upkeep.

Bringing Tradition Into Your Kitchen

Every time you hold the handle of your molybdenum steel knife, you hold the history of the samurai sword in the palm of your hand. The dedication of centuries of blacksmiths that came before now resides in your kitchen. It is a tool with a significant heritage.

Just like each painstakingly crafted blade is a work of art, so are the meals they help create. That’s why cooking enthusiasts and professional chefs use molybdenum knives to elevate the dishes that leave their kitchen. Every meal becomes a masterpiece by using a tool steeped in ritual and fashioned with passion.

The Benefits of Molybdenum Steel Knives

Like blacksmiths, blade sharpeners, and patterning artisans all contribute to fashioning swords, Japanese kitchen knives utilize different alloys in steel to cultivate the best blades.

Stainless steel always has at least 10.5% chromium, which helps resist corrosion. However, not all stainless steel uses molybdenum as an alloying element.

Molybdenum steel knives offer several benefits that make them popular among cooking enthusiasts. They resist corrosion even better than stainless steel alone, and the alloy’s added strength aids fine edge retention and durability. Molybdenum culinary knives are easier to sharpen than other alloys, enabling you to focus on food instead of upkeep.

Bringing Tradition Into Your Kitchen

Every time you hold the handle of your molybdenum steel knife, you hold the history of the. . . Show More >